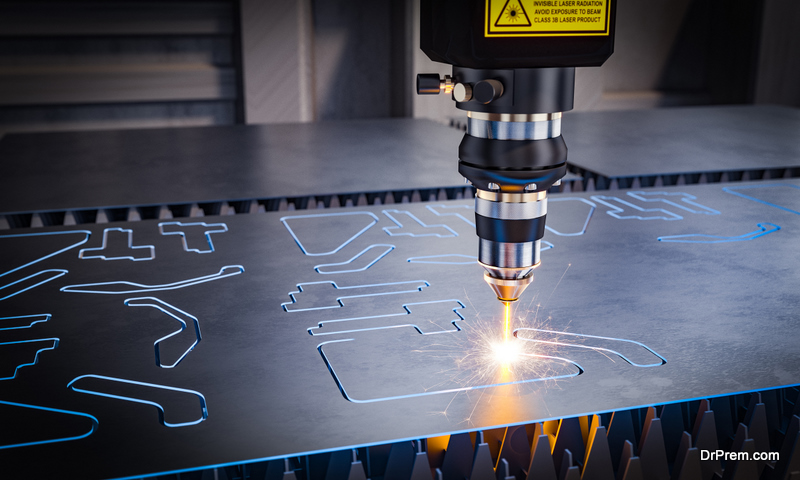

Despite these limitations, lasers remain a popular choice for metal cutting due to their many advantages.So, if you’re looking for a precise, fast, and safe way to cut metal, then lasers are the way to go. Let us check out the different types of lasers for metal cutting.

What is a laser and how does it work for metal cutting applications?

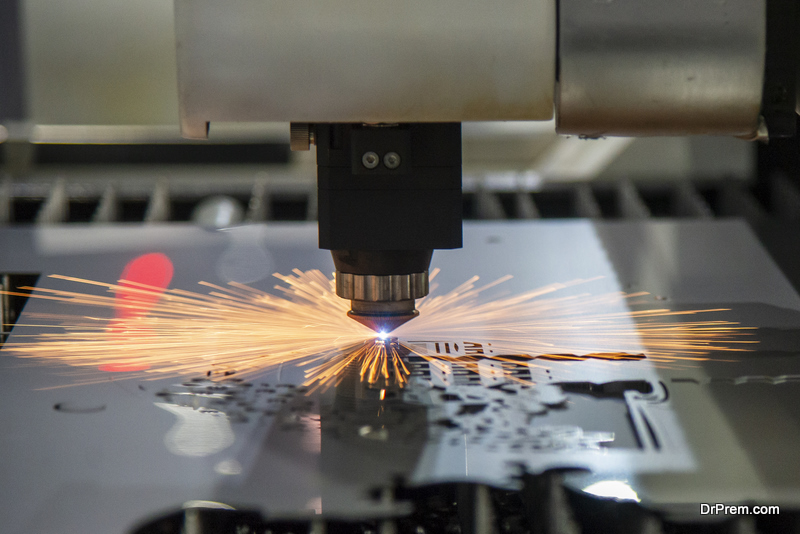

Lasers are often thought of as powerful beams of light, and in many ways, that is exactly what they are. But lasers are also unique in that they emit light that is all of the same wavelength and phase. This gives them the ability to cut through materials like metals with ease. When a laser is used for metal cutting applications, it works by heating up the metal to the point where it melts or vaporizes.

The heat from the laser is so intense that it can even cut through thicker metals like steel. And because the laser only heats up the specific area that it is pointed at, there is less risk of damaging nearby materials. As a result, lasers have become a popular choice for metal cutting applications in a wide range of industries.

The different types of lasers that are used for metal cutting.

CO2 lasers are the most common type of laser used for cutting metal. They can be used to cut a variety of metals, including mild steel, stainless steel, aluminum, and copper. CO2 lasers can also be used to cut non-metallic materials such as wood, plastic, and cardboard.

Fiber lasers are another type of laser that can be used for metal cutting. They’re becoming more popular because they’re more energy efficient than CO2 lasers and can cut faster. Fiber lasers can be used to cut the same types of metals as CO2 lasers, but they’re better suited for cutting thicker materials.

YAG lasers are the third type of laser commonly used for metal cutting. They’re not as common as CO2 or fiber lasers, but they can be used to cut a variety of metals, including aluminum, brass, and copper. YAG lasers are also typically more expensive than CO2 or fiber lasers.

How to choose the right laser for your metal cutting needs.

When it comes to metal cutting, there is no one-size-fits-all solution. The type of laser that you need will depend on a variety of factors, including the material you’re working with, the thickness of the metal, and the desired finish. To help you choose the right laser for your needs, here are a few things to keep in mind.

First, consider the type of material you’ll be cutting. If you’re working with thin sheet metal, you’ll need a different laser than if you’re cutting thicker plate steel. Second, think about the thickness of the metal. If you’re cutting thick material, you’ll need a more powerful laser. Third, consider the desired finish. If you want a clean, smooth cut, you’ll need a different laser than if you’re looking for a more rugged finish. By keeping these factors in mind, you can narrow down your choices and find the perfect laser for your metal cutting needs.

The limitations of lasers for metal cutting

Metal cutting is a vital manufacturing process that is used in a wide range of industries, from automotives to aerospace. In recent years, lasers have become increasingly popular for metal cutting due to their high precision and efficiency. However, there are some limitations to using lasers for this purpose. One issue is that laser beams can only cut through thin sheets of metal. This limits their usefulness for applications where thicker materials need to be cut, such as in the construction industry. Additionally, laser-cut edges can be very sharp, which can be a safety hazard. Finally, lasers are not effective at cutting through all types of metals; some metals reflect or absorb laser light, making them difficult or impossible to cut.

The benefits of using lasers for metal cutting

Lasers have been used for metal cutting for more than 50 years, and the technology has come a long way in that time. Today, lasers are able to cut through thicker and tougher materials than ever before, making them an essential tool for many manufacturing and construction projects. But what exactly are the benefits of using lasers for metal cutting?

For starters, lasers offer a high degree of precision. They can cut intricate shapes and patterns with ease, which is essential for many types of projects. Additionally, lasers are very fast, meaning that large projects can be completed in a shorter timeframe. And because there is no contact between the laser and the material being cut, there is less wear and tear on the equipment, which leads to fewer maintenance issues.

Finally, lasers offer a number of safety advantages. They create very little heat, meaning that there is a lower risk of fire or molten metal. And because they produce very little noise and vibration, they are much safer to use than traditional cutting methods such as saws or grinders.

Article Submitted By Community Writer